Design And Molding Process

Preparation of Production Patterns, Depending on the technical model and customer demands, they create production cutting patterns in computer environment for the most efficient evaluation of the fabric. If the fabric has passed the quality controls positively, it is molded in the dimensions and sizes requested by the customers in the computer environment. Print Washing and Ironing test is done.

You Can Also Create A Technical File For Your Brand For Free.

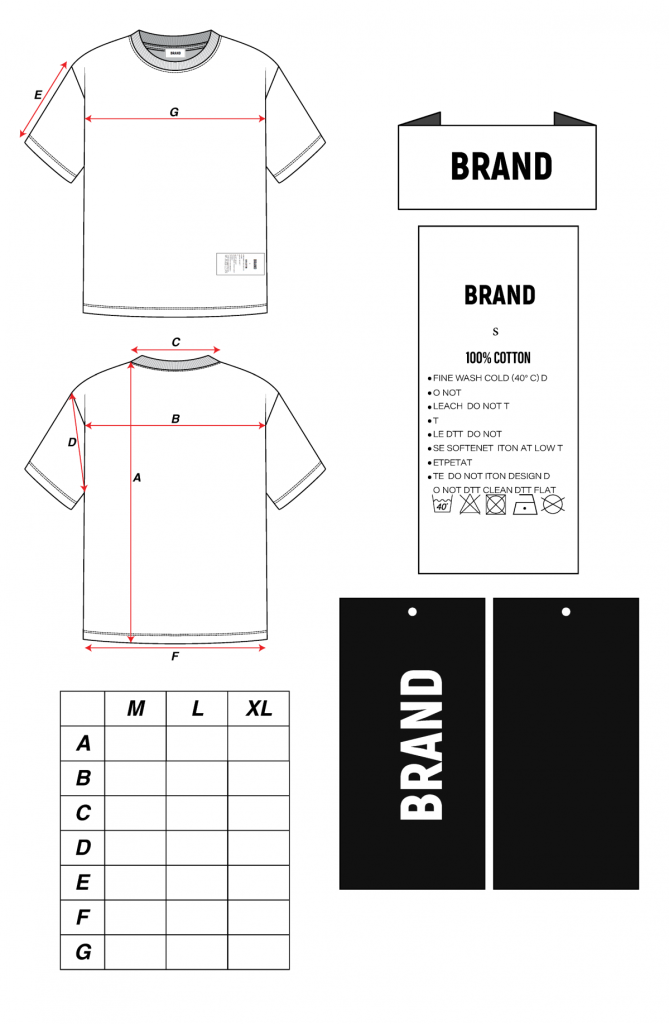

As an example, we will briefly explain how to create a T-shirt techpack specific to your brand. Creating a Techpack is usually a step taken to standardize and manage the production, distribution or sales processes of the t-shirt.

Here are the basic steps to create a t-shirt Techpack:

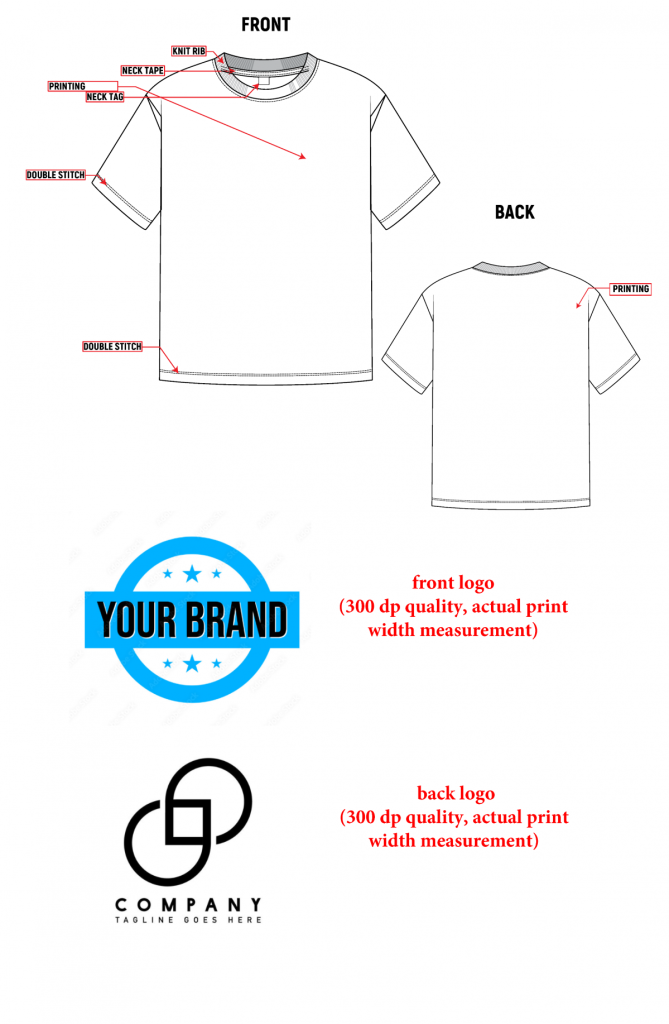

- Determine T-Shirt Design: The first step is to determine the design of the t-shirts to be produced or distributed. This design includes graphics, text or patterns that will appear on the t-shirt.

- Material Selection: Choose the material (e.g. cotton fabric, linen, hemp, polyester blend, organic cotton, etc.) and colors to be used for the t-shirts. Material quality and the intended use of the t-shirt play an important role

in this choice. - Size and Cut Selection: Determine in which sizes and cuts the t-shirts will be produced. For example, there may be standard sizes (such as XS, S, M, L, XL) or customized size options.

- Determining the Printing Method: Determine the printing method to be applied on the T-shirts. This can be a variety of techniques such as screen printing, digital printing, transfer printing or embroidery. The chosen

printing method is determined by the complexity of the design, its colorfulness and the t-shirt material. The printing pattern quality must be 300 dp and the width measurement must be given. - Labeling and Packaging: Determine brand labels on the t-shirts, care instructions and packaging details where necessary. This step reflects the brand identity and quality of the product.

- Production and Quality Control: Send us your technical file to produce the t-shirts. During the production process, quality control is carried out in accordance with the technical file and the compliance of the products with the standards is ensured.

- Documentation and Instructions: Prepare documentation to be included in your t-shirt techpack, such as instructions, care recommendations, or brand story. This includes additional information that will be made available to users of the t-shirts.

The T-Shirt Techpack creation process covers all processes, starting from the design of the product to the production and distribution stages. This process is important to maintain the quality of the t-shirts, manage production, and facilitate presentation to the consumer.